Slippy Kraken, innovations of slip-joint knife | Piratech | Seek Different

Piratech Knivessail with your friends

*This blog post is about the innovations on the Slippy Kraken, the first slip-joint folding knife we created, and the stories behind its design.

What could be innovated? The slip joint was invented 360 years ago and has remained largely unchanged until now!

Let me introduce you:

Five major innovations on the Slippy Kraken.

1. Changeable inlay

Thanks to the MagSnap System, we are able to make inlays simple without screws or glue to hold them. You can change the inlay at any time.

We put steel liners in the inlay and magnets in the titanium handle. The positioning cutout design ensures your inlays stay in place and do not move during use.

Now we can finally get rid of those ugly screws in the middle of the inlay and glue underneath. From now on, no more screwdriver or bouncing screws everywhere, and no more worry of whether it would be broken if you pry the inlay out when there's glue underneath the inlay.

We also leave a cutout for fingernails to get underneath the inlay, making it very easy to lift up the inlay.

2. Recurved lock spring

As we all know, classic slip-joint knives feature a curved handle spine, as illustrated in the picture below.

*Pic from https://content.artofmanliness.com/uploads/2018/01/Slip-Joint-Works-1.jpg

*Pic from https://content.artofmanliness.com/uploads/2018/01/Slip-Joint-Works-1.jpg

Can a slip-joint have a recurved handle? Could we have a different look and feel for slip joints?

When we conducted our research, we discovered that the curved handle spine designs served not only ergonomic and aesthetic purposes, but also for mechanical functionality. Those curves allow the back spring, or say the joint lock, to have the same curved shape instead of a straight steel bar.

The curve of the back spring causes more tension towards the blade tang than a straight one, which makes the lock more solid and harder to unlock. That tension also introduces a fidget factor, making the blade snappier both when open and closed.

We despaired because the project goal was to design a snappy slip-joint knife with a tiny, recurved Kraken handle that is comfortable in the hand and visually appealing. This discovery extinguished all hope; the laws of physics are absolute.

Will the slip-joint knife still retain its curved handle design for another 360 years? Could we make it different?

After a long period of research and debate, an idea of our metal engineer, who had worked for Honda, combined with the concept proposed by Damon, ultimately saved this project. We placed the large curved cutout on the underside of the back spring, rather than on the show side or the entire spring. Then, we make the back spring slightly curve downwards against the blade tang and let the blade tang push it back slightly to create the recurved shape that matches the handle shape.

We utilize this reversed stress successfully to create a recurved slip-joint lock spring without compromising the snappy action.

3. 118-degree mid-stop position

This was the first thing we had to deal with; for every new product, we strive to make all the details perfect and innovative, aiming to improve the user experience.

90° mid-stop was always a pain for slip-joint users. Since slip joints are a type of non-locking knife, it is not unusual for the blade to close during use. However, the 90° mid-stop did not perform its intended function well, failing to protect users' fingers effectively.

Therefore, we decided to make the Slippy Kraken a 120° mid-stop slip joint in the first place. To achieve that, many difficulties had to be conquered.

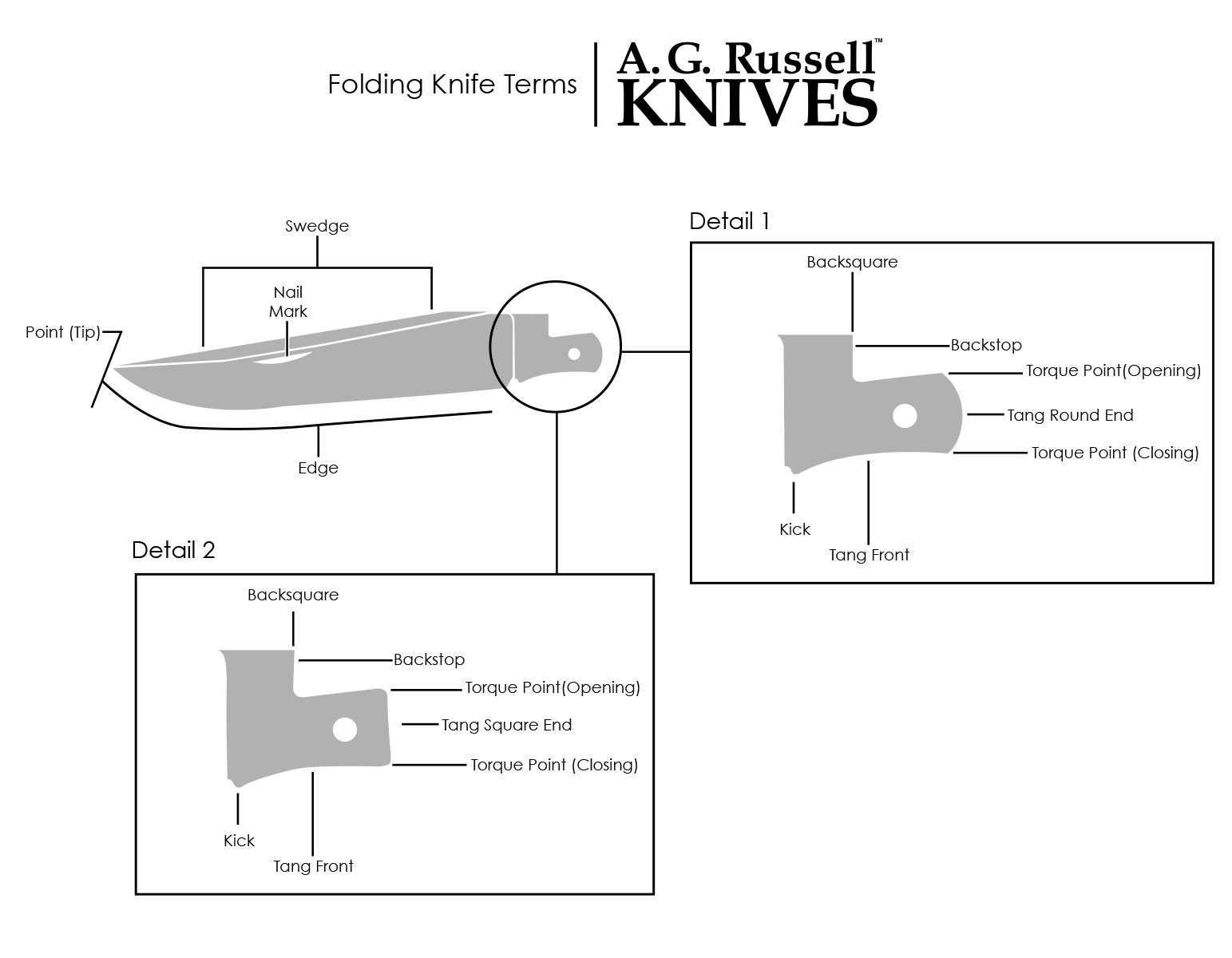

We have no case that could be studied. The classic 90° mid-stop blade tang is a simple square, while the back spring contact surface is flat. We must develop our unique blade tang shape to achieve a larger angle of mid-stop while maintaining the snappy tension.

*Pic shows traditional slip-joint blade tang

*Pic from https://agrussell.com/files/content/image/Folding%20Knife%20Terms-min.png

To achieve great tension and a smooth transition, we made the blade tang with two proud raises without an aggressive angle. To better team up with the back spring tension and handle grip position, we change the mid-stop angle from the planned 120° to 118°. With this final result, the risk of cutting your finger while closing the blade to the mid-stop position is essentially eliminated.

We can proudly say we have successfully combined the new and classic. This design angle for the Slippy Kraken improves not only the safety factor but also the fidget factor that people nowadays value. Because of the safe angle of the mid-stop, users can close the blade with one hand without fear, which simplifies the use of the slip joint, which was always required two-handed.

4. Adjustable lock spring tension

Another pain classic slip joint users have is the spring tension. Different knives, different brands, and even different production batches, but the same knife will have different tensions for the back spring.

Nowadays, slip joints differ from those of old, when spring tension was loose only to prevent the blade from free-falling. People prefer strong tension to make the knife more like a locking knife, allowing them to use it with confidence, which also increases the fidget factor. The biggest problem is that if the spring tension is too strong for you, it will be like the shoes are too small to fit in.

Therefore, we considered making the back spring tension adjustable so the Slippy Kraken is suitable for everyone!

Following the rules of MAYA (Most Advanced Yet Acceptable), innovation should improve users' experience enough to make people willing to try this new tool, yet simple enough for them to understand and learn to use.

We made the plug and three holes on the handle and the back spring. You can easily adjust the tension to the desired level by pulling the plug out and inserting it into the corresponding hole. Thanks to the MagSnap System again, the inlay covering the plug and holes could also be easily lifted to change tension settings without the need for any tools.

The solution was straightforward, right? However, MAYA also means easy for users and difficult for developers. Making it easy to learn is twice as much work as just adding a function; we have to think through the learning process and reverse it, simplifying it from 5 steps to 4 and then to 3 steps, and so on, after just adding a function. Those steps typically mean parts that support the function. Behind this solution, we have undergone two months of research and development, followed by three rounds of prototyping to test and recalibrate the position and structural stability.

5. Room-saving lock spring design

For a long time, the lock bar has occupied a significant amount of space in the handle, resulting in a tiny slip-joint knife blade. However, the pocket space is very limited and valuable; a pocket knife is meant to be a compact tool in your pocket when you need it.

We recognized that need, and we always focus on extremely tight fit designs to ensure every inch of space counts. We ensure that the blade shape is nearly identical to the handle room, providing both a functional and aesthetically pleasing blade shape.

For the lock bar, we were not using the smooth curve traction, but rather a design with numerous cutouts in the middle and back, allowing for more room for the blade while maintaining the structural strength the knife requires.

To achieve this, our metal engineer calculated the lockbar's need for strength and determined the optimal leverage point, considering three different settings of the lockbar tension and the maximum strength the breaking point could take. Ensuring the design and adjustments work out well.